Reflecting on my "roots" this pre Thanksgiving day!

The First 30 Years of My Life

Reflections on my early childhood!

My latter business life below!

The 1960's Pre internet days!

This is where I got all my information! Been reading this great magazine for over 50 years! American Vegetable Grower

Mostly written for my children and grandchildren to see.

As a young adult...never thought to ask my parents especially my dad about his early years and how he got started "Truck Farming" and how his dad immigrated to the U.S and was able to purchase the property in 1925 which I am writing about below.

● Had a high tech irrigated lettuce farm in the City of Glendale (Suburb now of Milwaukee, Wisconsin. Farm was located at corner of Florist and Baker Rd. East side of Baker Rd.Trade Press Media Publishing (now Trade Press Media Group) purchased the first two acre parcel on corner of Florist & Baker. They are still there! Johnson Controls is just South of the property. See aerial pictures further on in the blog.

● Specialized in growing Bibb, Romaine, Boston and Leaf lettuce. Had the highest quality lettuce by keeping soil moisture at optimum level, applying key minor elements as needed, keeping soil nutrients and PH at optimum levels.

● With the perfection of the art and science of lettuce growing(at the time), we became the Lettuce grower/supplier of choice for both Kohl’s and Sentry (Godfrey Co/Flemming Co.), the two top food chain stores in Wisconsin at the time. We were the only lettuce growers in the area! Similar lettuce was shipped in to the Chicago market where both Kohls and Sentry purchased their produce. Marketing was not a challenge. Wish I knew then what I know now...grateful to Kohl's produce buyer, John (Jake) Antonucci for the good relationship we had. Thanks Jake! (Jake's) last words to me were, "You'll be back in business again...It's in your blood." Not in the Lord's plan...but my interest did not die.

Looking back: How did I get to this point in my life?

Probably our two trips to Florida over Christmas time during my high school years led to a major interest in growing lettuce. We toured the whole state of Florida looking at all the vegetable producing areas.

Our home was behind the spruce trees.

The "garage" to the left of the "Chestnut" tree was our "Packing Shed" were we processed and packed the lettuce.

N.E corner of Florist & Baker Rd. Our home.

Site of Trade Press Publishing Co.now.

Maple tree is still alive and standing!

When an adjacent land owner to the West of us started to strip the topsoil off his land...had a potential problem with blowing dust-soil. Article in Glendale newspaper.

________________________________________________________________________

● Two challenges to a profitable crop were too much or too little water.

● As a result we designed and implemented a drainage system that drained the excess water from the soil in early spring at least 2 weeks earlier than without the system, thereby drying and warming up the soil early and producing our first crop while supplies from the South and West still had a high price.

● For lack of rain, we had an irrigation system that supplied water when and where we needed it. Actually hoped and prayed it would NOT rain. When it did rain, the rain was usually accompanied by high winds and small hail that cut and shreaded the lettuce plants. When the plants were small, they outgrew the damage from the rain and winds. Lettuce close to harvest did not survive. By planting early in the spring it helped that we could have 2 and sometimes 3 lettuce crops a year. When we knew there would be a damaging rain, Kohls was kind and helpful and purchased a lot, so the financial loss was not that great.

● Designed and built 3 “Plastic Houses” so we could get a head start on the season by transplanting lettuce into the field in mid April and thereby harvesting our first crop by June 1st, favorably competing with higher priced lettuce from “warmer” climates.

● As a result of the above, we produced two and sometimes three crops of lettuce a year!

● Attended the first Ag Expo in Tulare California in Feb 1968 to see and learn about the latest technology for growing lettuce. Also toured the lettuce growing areas from San Diego to San Francisco. Many years later attended the same event as a volunteer for Chapin Living Waters

(A Christian non profit started as a means to express Christian love to needy people in developing countries through small-scale drip irrigation technology) manning their booth...shared with Jain Irrigation Co. World Ag Expo Pictures

● As a result of economic expansion of the City of Glendale, and installation of sewer and water to our property, and with high taxes, we were forced out of business. Developed farm into Industrial Park over the next 7 years. Because of the new street (Baker) on West side of property, thousands of loads of ground fill were needed to bring the whole property up to grade level. It took several years to get all this fill because there was a recession going on at the time and not much new large building construction going on in downtown Milwaukee.

● Did not take up the offer of Sentry to work for them at their 300 acre farm near Sullivan Wisconsin and continue to grow lettuce for them...Their trucks went to Chicago each day and would have had a ready market. If I would have...I would not be writing this today. Looking back I see the hand of God directing me each step of the way. Also, more than willing to work 80- 100 hours a week in the summer months for myself than to do that for for an employer...as good as Sentry was! Never gave their offer any serious thought. Although several years earlier at the height of our business I did very briefly discuss with Jake from Kohl's the thought of specializing in just growing Bibb lettuce...and marketing it in Chicago. Thinking too much as a small family truck farmer than as a big grower. Didn't understand fully at the time what he meant when he asked what it cost me to produce a 24 head container of Bibb lettuce. Hadn't taken any managerial or cost accounting courses yet at that time.

Only regret is that I didn't take more pictures at the time. Missing pictures of the specialized machinery I had my cousin build for our operation. I guess I was more interested in the plant pictures. Thankful now that my hobby at the time was photography!

As Paul Harvey would say, "Now for the rest of the story." See my Linkedin profile. Richard Dassow

You could "click" on picture below and see all 56 pictures in full screen view!

Plastic covered house for germinating lettuce in early February

16 heads of Boston lettuce per box...boxes originally had broccoli in them from California.

Approximately 200+cases per day.

Wooden crates ready to be filled with Leaf, romaine and Boston lettuce.

These used crates came from California filled with celery.

A local man went around to all the stores, like Kohls and Sentry and picked up these crates and delivered them to me throughout the year. I took them in whatever condition they were and repaired if needed.

Summer Bibb lettuce (24 heads) were packed in pre used box's which came from Washington state with cherries in them.

All of the containers were recycled long before it was the thing to do!

Leaf Lettuce

Boston Lettuce

Field of Boston Lettuce transplanted in field end of April...as soon as soil dried up...as a result of water drained out as a result of buried tile. This picture 2nd week in May. Harvested by end of May and first week of June.

Family friend, Harry (Hartwig) Knudsen, who drove the Allis Chalmer's Model G tractor...pulling the vegetable planter. 2 people sat on the back of planter, alternatingly putting in lettuce plant in open furrow. Plant got a shot of water.

Rows were 3 ft apart. Plants were 8 inches apart in the rows.

Boston and Romaine lettuce were the only lettuce plants that were mechanically transplanted.

Harry's daughter Mary Ellen with her sheep.

Harry's son Jens several evenings a week in the summer delivered one or more truckloads of lettuce to Kohl's and Godfrey Company. No picture. Thanks Jens for the great help you were to us!

A few of my 3 Tractors

The same 3 tractors I had on our farm, I found at the Tractor Museum at College of the Ozarks

Boston Lettuce field.

2 inch Aluminum pipe bringing water to lettuce field.

Pipe crossing drainage ditch.

Drainage ditch on entire East side of property and also bisecting North quarter of property.

Drainage ditch was strategically planned and as a result entire property was tiled with 6" concrete tiles beneath soil surface. (see pictures of tiling process further down the page).

Summer Bibb

Rows 12" apart: Plants 6" apart in rows.

Seeded with 4 row planter on Allis Chalmers Model G Tractor

Summer Bibb

Leaf Lettuce

2 inch Aluminum pipe bringing water to lettuce field.

Pipe crossing drainage ditch.

Drainage ditch on entire East side of property and also bisecting North quarter of property.

Drainage ditch was strategically planned and as a result entire property was tiled with 6" concrete tiles beneath soil surface. (see pictures of tiling process further down the page).

This Summer Bibb planting was "hand transplanted."

Summer Bibb

Rows 12" apart: Plants 6" apart in rows.

Seeded with 4 row planter on Allis Chalmers Model G Tractor

Summer Bibb

Leaf Lettuce

Where we purchased our lettuce seeds. Great company! Still in business!

Red and Green Leaf Lettuce in packing shed.

24 heads packed per box after washing each head in almost ice-cold water.

Danny, one of our best high school helpers during the summer.

Last I heard, he was working on an organic vegetable farm in Northwestern Wisconsin.

24" plastic tubing with 2" holes every 12 inches. When temperature got too warm, thermostatically controlled fan opened and let in cool outside air which was distributed evenly over the length of the plastic house.

Beds inside the plastic house had heating cables also...to help germinate the lettuce seeds..

Gas hot air furnace for heating the "plastic houses"

Set of 3 "Plastic Houses" Cold frames to the left of them.

Each "house" was thermostatically temperature controlled by fans with the plastic tubing distributing the cool air the length of each house.

Rafters were wooden 2x4's. Plastic tubing was not even though of to use at the time.

|

Bibb Lettuce Plants |

|

Dark green and Light green leaf lettuce before transplanting to field. |

| |||||||||||

Heating cables in cold frameCold frames where Bibb Lettuce plants were started for later transplanting to the field. |

Bibb Lettuce plants. Showing the extensive root system. Soil mixture was 1/2 peat and 1/2 torpedo sand.

Tiling a field: 6 " concrete tile were buried 2-3 feet beneath the soil. Paralel tile lines approximately 30 feet apart. Draining into drainage ditches on East side of property and also bisecting northern section of farm. (size of farm: 330 ft wide by 1500 ft long) Fields dried up much sooner in spring...up to 2 weeks sooner because of the quicker drainage of the wet soil in spring after snow melted..., so lettuce could be planted and or seeded by end of April...and harvested by June 1st.

Tiling done by H & K Concrete Products of Grafton Wisconsin.

Tile lines drained into this county dug drainage ditch. Probably dug in early 1920's. East and West ditch bisecting 11 acre property on North end. Similar ditch on East perimeter of property running in South direction, draining into Crestwood Creek, Lincoln creek and then into Milwaukee River.

Irrigation

Entire 11 acres were irrigated. 300+ foot deep well. 5" casing down to 90 feet and then diameter reduced to 4". 5 horsepower submersible pump, pumping 3500 Gallons of water per hour...up to 12 or more hours per day... eventually had to be lowered to the 90' depth (as far as it could be lowered because of reduced size of casing. Water table was constantly being lowered...presumably because of Cedarburg, Wisconsin wells which were lowering the water table. We were the only or last vegetable farm in Glendale.

2 inch aluminum 20 ft length sections of irrigation pipe. Each line 300 ft in length.

Each 20 ft section had a 1/8" Rainbird sprinkler head.

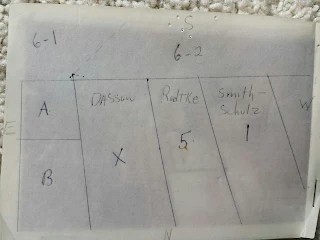

A few aerial pictures of our farm taken around 1954 with my first 35 MM camera, Kodak Retina Reflex...at around 1,000 feet. Looking in South direction.

6.1 and 6.2 was Globe Union property. Now Johnson Controls.

As you can see even without the drainage system installed at this time, our fields were being worked before our two neighbors to the right side of us.

End of an Era: Topsoil Removal from farm.

This is a LIVE link!

Please come back again...in process of updating...will add more pictures and comments.

_____________________________________________________________

On our recent trip to Branson, Missouri, we visited College of the Ozarks. College of the Ozarks

They had a Tractor Museum and I was surprised to see 3 restored tractors. Same as I had on my lettuce farm many years ago.

Ford 8N- on the right side.

Allis Chalmers Model G- on the left side.

International Cub-Yellow tractor in the center. Ours was the same but the color was red.

Reflections on my early childhood!

Life after lettuce business ended

My other Blog: Finishing Well

Bloom where you are planted! We

have all heard this phrase so many times that maybe we don't understand

what it really means. Google the phrase...you will see what I mean. Some

very good secular or worldly advice.

Be "rooted", "grounded" and "grow" and so rise to the top of your

"field"...and "bloom" where you are "planted" ...using the "Abilities",

"gifts" and "Strengths" God has endowed you with.

By doing the above...we potentially can rise to the top of our "field".

But WHY should we Bloom Where We Are Planted?

As a believer in Jesus Christ and desiring to be a good steward and a

faithful "follower" of Jesus on our way to glory...we can be a light

for others to see the Truth.

●"The

Lord

created each of us individually with different Spiritual Gifts,

Passions,

Abilities, strengths and a unique personality with different

experiences. Helping each other put the pieces of the seeming puzzle

together so we each can

be most effective in our families, church, community and the world and

finish

our lives well and leave a legacy that gives glory to the LORD so when

we stand

before Him one day, we will hear, "Well done, my good and faithful

servant."

Isn't that what we would like to hear one day?

"God has created each of us with a unique contribution to make in our world and our times. No other person has our same abilities, motivations, network of friends and relationships, perspectives, ideas, or experiences. When we, like misplaced puzzle pieces, fail to show up, the overall picture is diminished." Richard Stearns: President of World Vision U.S.

Quote from his book: The Hole in our Gospel